A Clean Freshwater & salt Magnetohydrodynamic Marine Drive.

This type of Marine Drive is Completely Clean of All Forms of Pollution. Having No Use of Any Electrical Devices or Powersource.

To Achieve this. One needs to only allow The Properties of Our Chosen Materials to do as they wish. So, what do We have? Water, Steel, Neodymium Magnets, Clear Epoxy & Bismuth Brass.

What will We have? One Center Shaft. With no moving Internal parts. One Outer Ring. With no moving Internal parts. With the Shaft Centered inside the Ring.

Let’s Build this Toy. This Enigma. This Devine Creation from the mind of KnowOne2Know.

You now have 3 DXF, Cad, Zip files. It is Completely up to You to open & use the Files in Your 3D Cad Software programs. On the Left is the Full 3D Cad files. Please make a Copy to Play with. While Saving the Original to make more copy’s if needed. The middle one & the one on the right. Are for 3D Printing. So, You will have something to hold on to. If you can See it & Hold it. It will make Sense.

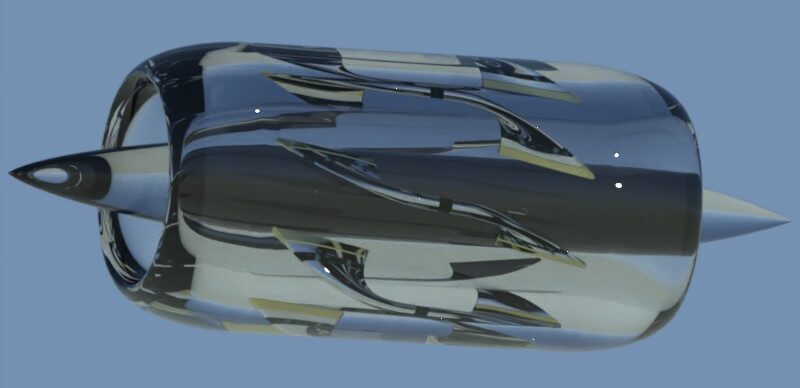

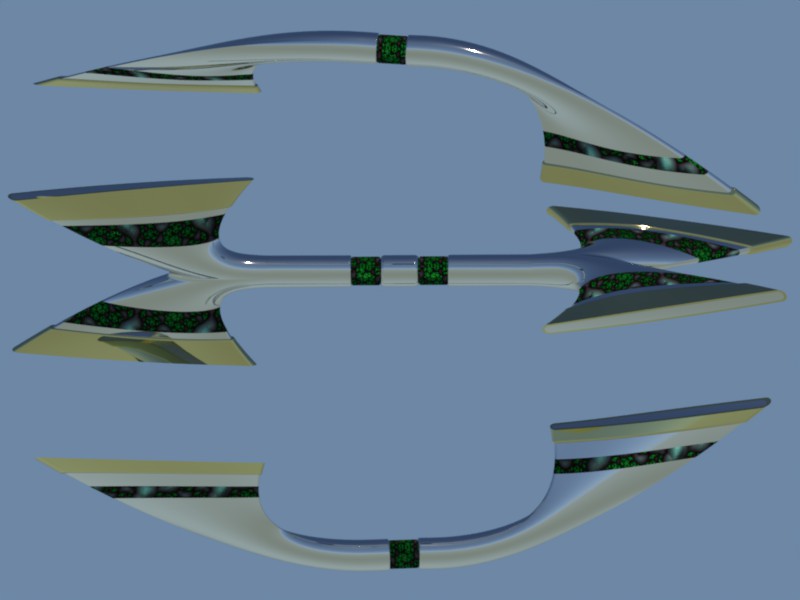

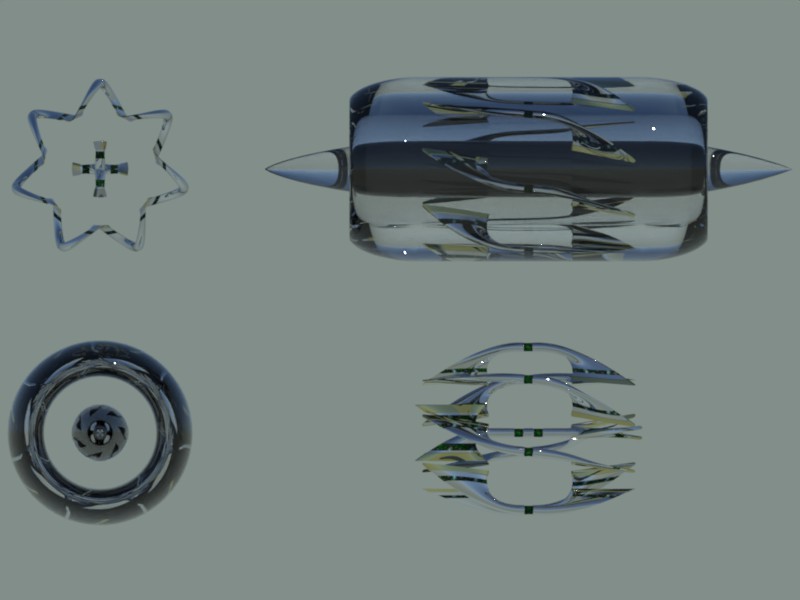

Here You have the Shaft with 4 ends. Plus 2 of the 7 Bars for the Ring. With 2 ends each. See how they have a smooth twist? Well, A Natural Organic Flow is a Key part of How & Why this System works.

Color code. The Steel looks like steel. The Bismuth brass looks like brass. The Neodymium Magnets look like Green Gems. While anytime you see Glass. That is Clear Epoxy.

Here You have the Side Views. One with Epoxy Shell, One without. Plus 2 End Views. One with Epoxy Shell. One without. The top left is the end view of the bottom right. Anyway, the 7 Bars in the Ring are NOT touching each other. It only looks that way because the Front of One bar is in the Direct line of site of the next bars End. While the Ends of the Shaft are at 90 degrees of each other. This is another Key part.

More Key parts.

Magnetic Alinement. Every Magnet is Aligned to the Axis of the Shaft. With one of the Poles Pointing Straight to the Axis. While the other pole is pointing Straight Away from the Axis. This is for All Magnets, Shaft & Ring. Any North or South can point in or out. The Magnets can be Placed Anywhere along the Axis. As well as Any distance from the Axis. Even if the Shape of the magnet is Not Aligned to the Axis (It may happen). Its Polarization Must be Aligned to the Axis. P.s. The Tips on the left are North to North. While the Right are South to South facing for the Shaft to Ring. In the Flow Chamber Left is all north. Right is all South. This is Not a Choice! It is a Rule!

How to find the Distance between the Shaft & Inside of the Ring. The Chamber were the Water Flows & is Used as the Propellant. Choose One of the Magnets for the Shaft & One for the Ring. These are the Magnets You have Chosen for Your MHD Toy. I say Toy because these Cad files here. Are to make one MHD that is about. 80 cm long Shaft with about 28 cm outside diameter for the Ring. With 4 cm flow chamber. Sorry I’m back. I was getting another Beer. So now hold the Two Magnets Very Lightly with the tips of your thumbs & fingers, One each on each hand. With Opposing polarities. The lighter the touch the Better. Now slowly bring them together. When Any Resistance is Seen or Felt. Mark That Distance. Whatever it is. Divide that # by 5. Then Multiply by 4. Or use 4/5th. This is the Measured distance between the Magnets. Used for the Distance between the Shaft & Inside Surface of the Ring. Not the distance between the Magnets. Because the tips are Steel Cylinder. Then Magnet. Then Steel covered in Bismuth brass. Even though You measured between Magnets. It is Still the Distance between the Shaft Surface & Inside surface of the Ring. What I’m say’n is You have the 4/5 Distance. Yet after Everything is aligned. The true distance between the Magnets will be Farther. Not a Choice! A Rule!

Using this Distance as Your starting point. You can now use the Cad files. To be Bulit around the found distance. Yes, I said that correctly. We are Not Forcing anything. We are Building around the Proprieties of the MHD Materials. This Design Will Conform to the MHD System. This MHD system Will Not Conform to Anything or Anyway You Wish! Not a Choice! A Rule!

Angles. The Shaft has 4 Tips. While One Rod in the Ring has Two tips. So, 14 Tips in the Ring. Because it has 7 Rods. Now look at the center of the Shaft & One Rod. It’s a nice Cylinder that Smoothly transform into an almost flat tip. This is Good because the Tips are where the Magnetic fields Extend out to Form Our Magnetic propellers. That’s Right! Both the Shaft & Ring have Extending Magnetic Propellers. That Extend into the Flow Chamber. The Shafts are facing out. While the Rings are facing Inwards. The Tips on the Shaft are 9 degrees off axis. While the Rings Tips are -9 degrees off axis. This is so they form an ( X ). While Facing each other. For this Design the Shaft will Spin Clockwise. While the Ring will spin Counterclockwise. When looking at it from the Left. Not a Choice! A Rule!

Bismuth brass. True We all know the Devine Elegance of Bismuth brass. Especially when polished. As All Parts of this MHD should be Polished. Just Not the Magnets. Anyway, Bismuth brass has Magnetic properties that are necessary to keep the Magnetic fields in place. Remember our Magnetic propellers? Most propellers are thin. Yet Magnet fields Like to Bulge outward. So, We are using Bismuth brass as a break, or stop point. Is this perfect? Hell No. Yet it is the best alloy you have. Because it is NOT perfect. The magnetic fields will bulge out. Once they leave the tips. To overcome this Flaw. Two things will need to happen. The Distance between the Shaft & Ring. Aswell as the Spacing between the Rods in the Ring & Shaft. You need room for water to be in a Neutral state. Between the magnetic fields in the Flow Chamber. Not a Choice! A Rule! If You ever do have an Acceptable Alloy. I suggest You cover all parts of the MHD Shaft & Rods. Yet I do not see that to be for another 3 to 4 hundred years at your present intellectual rate of development. Sorry to offend you. I just say it as I see it.

All Magnets are aligned to the Axis! Yet EVERYTHING is Centered on the FLOW CHAMBER! Going for a 40 ouncer now. Be right back.

Anyway, I am Not trying to drive anyone crazy. This is a Step-by-Step instruction. It’s just that once you get to this step. You do need to go back and readjust the past step. So, you may move onto the next or the One after. I Highly Suggest You Reread this Website 4 or more times.

As for Cohesion/Adhesion & Diamagnetism of Water. This should be Self Explaining. Water Loves Everything. So, it will grab on to everything. Like itself. Except it Hates Magnetic Fields. All Magnetic Fields North & South. Especially when the Fields are intertwined. This means it is Repelled by all magnetic fields. So, if a small chunk of water is moved by the magnets. Especially when the magnetic fields are holding the water in a rotating linear Path. Then Some more water will be Pulled too. Maybe This is How the Magnetic Propellers Work? Really that simple? I.D.K.

Clear Epoxy. This should be simple. Put the Shaft in a bucket. Fill the bucket with Clear Epoxy. When Dry & Hard. Give it to Someone that KNOWS How to use a Lathe. Along with a picture of the Shaft. Pay Him to make it look like that. The 7 Rods. find a way to hold them in place. Then do it again. Just a thought while I’m hav’n a 40-ounce boilermaker. Maybe You should just pay Others to do the whole thing. You know for your Own safety.

You’re Going to Love This.

How to hold the Shaft in the center of the Ring. Then Rotate the Shaft Clockwise & Ring Counterclockwise. Do it Anyway you can. I do not care. Truly I care Not.

Because I use what is called a Magnetic Stabilizer. That is, it’s Primary function. To stabilize the Magnets. To keep them from becoming Demagnetized. One for Each Rod & One for the Shaft. They work all the time. No need for power or anything. Simple things. Yet when spinning. Because the Ring is spinning. They Project a force. It’s not a large force, short range. This force if in close enough proximity to the one in the Shaft. Will Force the Shaft to stay Locked in place within the Ring. While Forcing the Shaft to Spin in the Opposite direction that the Ring spins. It could work vise/versa. Only it is 7 to One. That means the 7 in the Ring will force the Shaft to spin. Not Shaft forces the Ring. So, all I need to do is Spin the Ring. Then the Shaft will Spin in the Opposite direction. Without Anything Touching it.

The Other Part is Why? How & Why this force works? That is because of ***. Really? You need Me to Explain? It Works because of this Naturel Phenomenon, called ***. That’s correct. You Do Not Need to Know! I know because I Know. You need to learn. I also Know how to Shut down All M.H.D.s of this type. Without causing any damage. Not that I would. You have every right to play with your toy.

Magnets Should be Nickel Plated as most are. They should also be coated with Epoxy Heavily Mixed with Fine Paper Dust. Like One would find in a Paper Mill. This is to Ensure the Magnets Never have any Physical Contact with Anything.

To Sum this up. This Entire Website is for Entertainment. (A Puzzel) for You. Because I Distorted All Measurements, Distances, Angles, Sizes & Any other thing you should be able to think of. I did this so you would Learn. Not have it Handed to you on a Rotting Wooden Plater. Should you attempt to construct this & you fail. O-well, that’s on you. Should you be upset? Then Leave, Please Leave. Do Not Attempt to construct this or Anything. Do not Attempt anything. Ever! I Will Not be Held Accountable for Your Intellectual ignorance. It is Your choice to be reading this. Not Mine!

Sorry about that last part. It’s just that some Loser’s truly believe. I owe them everything. Even when I received No Assistances from them or Anyone. In Any Form. Now to the Next page. Yes, Go to the top & click on Donate.